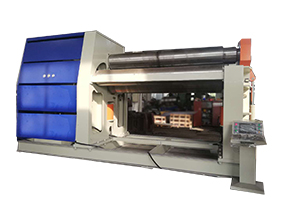

GJW12H-12X2000 Line

The automatic rolling machine production line is the automatic metal rolling round processing and production equipment developed on the basis of the rolling machine, which realizes the automatic production of the whole process, such as automatic lamination, automatic taking, automatic feeding, automatic rolling, automatic discharging, etc. The high degree of automation of the equipment can effectively guarantee the quality of products, improve production efficiency, reduce production costs, reduce labor intensity. It is widely used in manufacturing thin-walled pipes, automobile oil barrels, ventilation ducts, chimneys, filters, solar water heaters, automobile exhaust pipes, liquid (gas) tanks and so on.

Features of automatic plate rolling machine production line:

1. The code material platform is equipped with an automatic divider, which can divide the sheet materials automatically, effectively preventing multiple sheets from absorbing each other and taking materials at the same time.

2. Automatic material taking device adopts large suction vacuum sucker with buffer, with reasonable structure and low failure rate. The suction cup guide column has spring buffer, the air pipe is connected to the metal guide column, the structure is stable and not easy to fall off. The adjustable sucker support can adjust the sucker position according to the length and width of the rolled workpiece to ensure the stability and efficiency of the material taking. The lifting device is equipped with a stable guide bar to ensure fast and stable lifting and walking. High power cylinder or servo motor of high quality is selected for fast lifting speed and stable operation without jitter.

3. Automatic aligning feeding device is composed of aligning device installed on the feeding platform and feeding device. The aligning device adopts the two-side moving aligning system and is equipped with multiple sets of rolling aligning wheels, which are suitable for aligning of different sheet materials with great difference in plate width. When the feeding device pushes the plate, the aligning device is always in the aligning state to ensure the correct feeding attitude of the plate.

4. Automatic plate rolling machine is a four-roller plate rolling machine produced by our company.

5. The automatic discharging device will automatically push the workpiece to the external connecting platform after the winding is completed.

Our Services

Pre-service:

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service

1.We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

2.All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can¡¯t solve your problem , our engineer will go to your factory to help you on spot.

3.Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Contact US

Mary

Nantong Guoji Machinery Equipment Co. LTD

E-mail: Info@guojimachine.com

sales@guojimachine.com

Mobile/Wechat: +86 18796137573

QQ:570506110

| Previous£ºGJW12H-10X2000Line |

| Next£ºGJW24-75 |