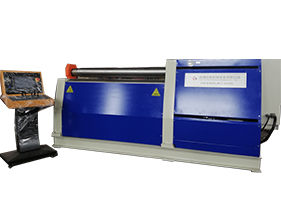

GJW12H-25X2500JS

Product Description:

The machine has pre-bending function for plate edge ,and can bend roll the plate one time without any thing re-rolling with combined procedure or pre-bending and bending roll into shape. The upper roller and the down roller are the main drive rolls, two side rolls up-and-down movement is controlled by hydraulic drive. The up-and-down displacement of the down and side rollers are controlled by computer.Automatic leveling,display by screen , high synchronization precision ¡À0.2MM.Turnover bearing body dumping and reset is done through hydraulic transmission.The upper roll end has balance equipment to be convenient take of the rolled cylinder and working pieces.There are moveable independent operation table for easy moveable operation.

Structural Features:

1.The four-roller bending machine adopts a torsion-axis synchronous structure, and the four-roller coiling machine has high precision and roundness after being rolled up!

2.Full hydraulic motor drive, four-roller coiling machine is environmentally friendly and energy efficient.

3.Straight side is short and the pre-bending effect is good! More suitable for roll cones.

4.The four-roller reeling process is completed in one pass, including bilateral pre-bending. The four-roller reeling machine is fast, efficient, and easy to operate, requiring only one operator.

5.With automatic alignment and clamping function, the plate will not slide and run off.

6.The four-roller bending machine has anti-overload and hydraulic protection functions.

7.With anti-wear, permanent lubrication-free features.

8.The diameter of the reel is small (the four-roll bending machine can roll a cylinder that is less than 1.1 times the diameter of the upper roller, and the linear sliding-guided rolling machine can have a diameter of 1.4-0.5 times the diameter of the upper roller).

Selection Guide

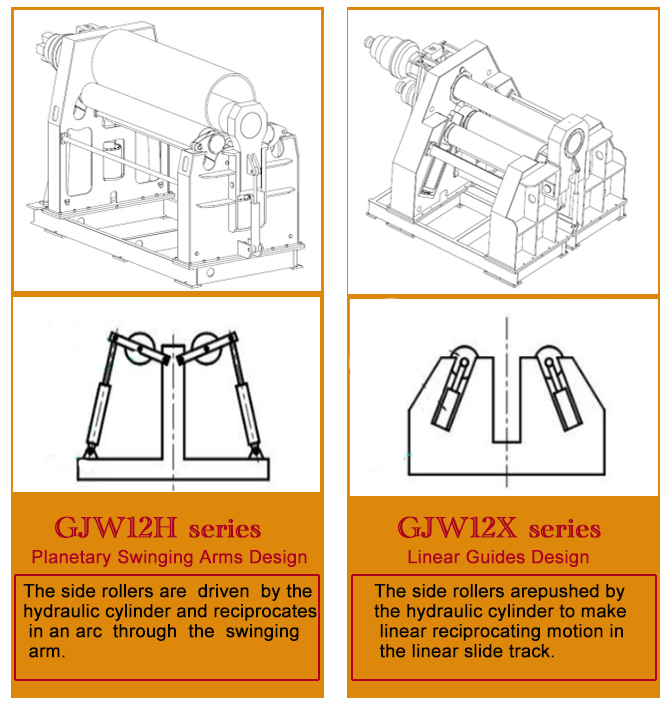

Our company has two series of the four rolls plate bending machine ¡ª¡ªGJW12H\GJW12X

HOW CAN CHOOSE THEM?

WHAT ARE THE DIFFRENCES BETWEEN THEM?

Selection guide

T¡Ü30mm We recommend GJW12H

30mm<T<60mm GJW12H \GJW12X are fine

T¡Ý60mm We recommend GJW12X

|

Model |

Max.Roll Thickness |

Max.Roll width |

Upper roller diameter |

Side Roller diameter |

Motor |

|

|

mm |

mm |

mm |

mm |

Kw |

|

GJW12H-4x1500 |

4 |

1500 |

140 |

120 |

2.2 |

|

GJW12H-6x2000 |

6 |

2000 |

190 |

170 |

4 |

|

GJW12H-6x2500 |

6 |

2500 |

220 |

180 |

7.5 |

|

GJW12H-8x2500 |

6 |

2500 |

240 |

180 |

7.5 |

|

GJW12H-12x2000 |

12 |

2000 |

260 |

200 |

11 |

|

GJW12H-12x3000 |

12 |

3000 |

300 |

260 |

22 |

|

GJW12H-16x2500 |

16 |

2500 |

280 |

230 |

15 |

|

GJW12H-16x4000 |

16 |

4000 |

420 |

330 |

37 |

|

GJW12H-20x2000 |

20 |

2000 |

300 |

260 |

22 |

|

GJW12H-20x3000 |

20 |

3000 |

360 |

330 |

15 |

|

GJW12H-25x2500 |

25 |

2500 |

390 |

310 |

30 |

|

GJW12H-30X2500 |

30 |

2500 |

420 |

330 |

37 |

|

GJW12H-30x3000 |

30 |

3000 |

460 |

340 |

37 |

|

GJW12H-35x3000 |

35 |

3000 |

510 |

410 |

37 |

|

GJW12H-45x2500 |

45 |

2500 |

510 |

410 |

37 |

|

GJW12H-50x2500 |

50 |

2500 |

560 |

440 |

55 |

|

GJW12H-60x3000 |

60 |

3000 |

670 |

510 |

108.5 |

Our Services

Pre-service:

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service

1.We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

2.All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can¡¯t solve your problem , our engineer will go to your factory to help you on spot.

3.Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Contact US

Mary

Nantong Guoji Machinery Equipment Co. LTD

E-mail: info@guojimachine.com

sales@guojimachine.com

Mobile/Wechat: +86 18796137573

QQ:570506110

| Previous£ºGJW12X-100X3200 |

| Next£ºGJW12H-6X2000 |