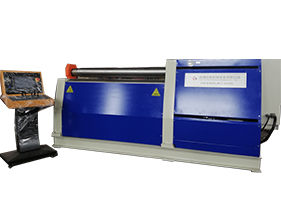

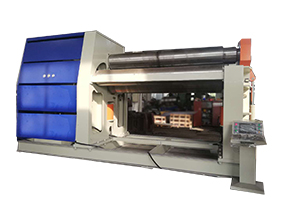

GJW11Y-60X2500

Product Description

The machine widely used in petroleum, chemical industry, cement, boiler, shipbuilding, aviation, water conservancy, power transmission towers and other machinery and equipment.The upper roll is located at the center of two lower rolls and is directly driven by dual hydraulic cylinders to ove vertically. the output gear on main speed reducer is used to mesh the gears of both lower rolls for rotation so as to provide torque for rolling plate. Metal plate is located among three working rolls and subsequently continuously bent under pressure of upper roll and rotation of lower rolls to generate perment plastic deformation on plate so as to roll the plate to required shape .

Structural Features

1. The system adopts brand PLC and touch screen to ensure smooth operation of software and hardware, high precision and good stability. And has sufficient expansion port, rich machine automation configuration;

2. Six mechanical limits of the whole machine cooperate with the soft limit of the system to implement interconnection and interlock;

3. Solid forging roller shaft, high strength and good toughness;

4. Discharging support, hydraulic turn over, reset, one-button operation;

5. The whole system adopts the hard tooth surface reducer, plate welding shell, hard tooth surface helical gear, high transmission efficiency, small vibration, low noise;

6. YZR crane metallurgical motor is connected with frequency-sensitive rheostat to ensure reliable operation of frequent starting, braking and reversing.

Selection Guide

Our company has three series of the three rolls plate bending machine

——GJW11S Hydraulic pre-bending

GJW11 Hydraulic Non-bending

GJW11Mechanical Symmetrical

HOW CAN CHOOSE THEM?

WHAT ARE THE DIFFRENCES BETWEEN THEM?

Technical Parameter

|

Model |

Max.Roll Thickness |

Max.Roll width |

Upper roller diameter |

Side Roller diameter |

Motor |

|

mm |

mm |

mm |

mm |

Kw |

|

|

GJW11-12*2000 |

12 |

2000 |

250 |

145 |

5.5 |

|

GJW11-12*3000 |

12 |

3000 |

290 |

150 |

7.5 |

|

GJW11-16*2000 |

16 |

2000 |

260 |

150 |

7.5 |

|

GJW11-16*3000 |

16 |

3000 |

330 |

165 |

11 |

|

GJW11-20*2000 |

20 |

2000 |

310 |

165 |

15 |

|

GJW11-20*3000 |

20 |

3000 |

375 |

200 |

Y18.5 |

|

GJW11-25*2500 |

25 |

2500 |

380 |

220 |

22 |

|

GJW11-25*3000 |

25 |

3000 |

410 |

220 |

22 |

|

GJW11-30*2500 |

30 |

2500 |

410 |

235 |

22 |

|

GJW11-30*3000 |

30 |

3000 |

450 |

250 |

30 |

|

GJW11-35*2500 |

35 |

2500 |

450 |

250 |

30 |

|

GJW11-35*3000 |

35 |

3000 |

500 |

260 |

37 |

|

GJW11-40*2500 |

40 |

2500 |

500 |

260 |

37 |

|

GJW11-40*3000 |

40 |

3000 |

540 |

275 |

45 |

|

GJW11-45*3000 |

45 |

3000 |

590 |

300 |

45 |

|

GJW11-50*3000 |

50 |

3000 |

610 |

340 |

55 |

Our Services

Pre-service:

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service

1.We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

2.All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can’t solve your problem , our engineer will go to your factory to help you on spot.

3.Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Contact US

Mary

Nantong Guoji Machinery Equipment Co. LTD

E-mail: info@guojimachine.com

Mobile/Wechat: +86 18796137573

QQ:570506110

| Previous:GJW11Y-45X3000 |

| Next:GJW11S-25X4000 |