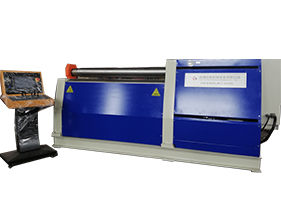

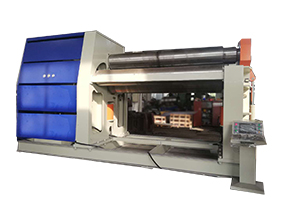

GJW10-3X1500

Product Description

The automatic hydraulic 2 roller plate bending machine is a new type rolling machine on which a roll is made of steel and the other roll comprises a steel core covered by elastic layer(rubber roll). The plate can be arranged between rolls with adjustable distance. With process of contracting, pressurizing, rubber roll deforming, the plate is deformed and the rolled to specified shape when both rolls are driven to rotate. The equipment has advantages of forming in one piece, high production efficiency, high geometric accuracy of finished product, good surface quality and simple structure with fewer rolls. PLC(programmable logic controller) is adopted on equipment, so operation is simple and numerical control of production process can be easily realized.

Structural Features

1¡¢The main rubber roller is specially processed by Japanese professional technology.

2¡¢The entire hydraulic system has a small size, low noise, stable pressure, and a one year warranty.

3¡¢The control system uses PLC control, control cabinet main electrical components one year warranty and lifetime maintenance.

4¡¢The main frame steel plate welding structure, post-welding aging treatment.

5¡¢Parts must be shot blasting slag, rust, after the anti-rust primer, putty painted topcoat. The appearance of the whole machine is clean and beautiful.

6¡¢When the equipment is delivered, with the accessories of the machine, common tools, operating instructions, electrical diagrams.

Technical Parameter

|

Model |

Max.Roll Thickness |

Max.Roll width |

Yielding limit of sheet metal |

Rolling speed |

Motor |

|

mm |

mm |

Mpa |

m/min |

Kw |

|

|

GJW10-1*300 |

1 |

300 |

245 |

4.5 |

2.2 |

|

GJW10-2*400 |

12 |

3000 |

245 |

4.5 |

2.2 |

|

GJW10-2*600 |

16 |

2000 |

245 |

4.5 |

2.2 |

|

GJW10-3*700 |

16 |

3000 |

245 |

4.5 |

3 |

|

GJW10-3*800 |

20 |

2000 |

245 |

4.5 |

3 |

|

GJW10-3*1000 |

20 |

3000 |

245 |

4.5 |

3 |

|

GJW10-3*1250 |

25 |

2500 |

245 |

4.5 |

3 |

|

GJW10-4*1300 |

25 |

3000 |

245 |

4.5 |

3 |

|

GJW10-4*1500 |

30 |

2500 |

245 |

4.5 |

3 |

|

GJW10-3*1800 |

30 |

3000 |

245 |

4.5 |

3 |

|

GJW10-3*2000 |

35 |

2500 |

245 |

4.5 |

3 |

Our Services

Pre-service:

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service

1.We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

2.All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can¡¯t solve your problem , our engineer will go to your factory to help you on spot.

3.Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Contact US

Mary

Nantong Guoji Machinery Equipment Co. LTD

E-mail: info@guojimachine.com

Mobile/Wechat: +86 18796137573

QQ:570506110

| Previous£ºGJWZ-16X2500 |

| Next£ºGJW10-4X1500 |