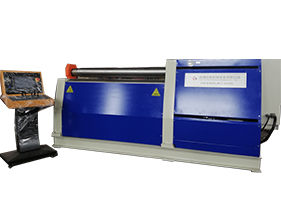

GJW11S-25X4000

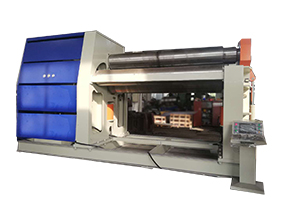

Product Description

The three roll hydraulic plate rolling machine features linear hydraulic movement of all three rolls: Vertical top roll and horizontal bottom roll movement. This concept offers some significant advantages over other 3 roll concepts regarding pre-bending, bending quality and work-piece handling.

The following basic operations can be used:

1、Pre-bending of sheet edges

2、Rounding of sheets into cylindrical shapes

3、Press bending of cones and cylinders

Structural Features

1、GJW11Sseries Upper-Roll 3 Roller Hydraulic Plate Rolling Machine produced by Japanese advanced technology.

2、High-precision end of the pre-bending, set the length of the straight edge freely; direct pressure on the pre-roll bending, high-precision can be completed in advance of the end of the bend.

3、CNC control, high productivity products rolling process parameters NC, simple and substantial increase in efficiency.

4、 The roller assumes the bulging form on products accuracy hyper group, have asking a roller to coordinate adjustment ,continuous bending on time of roller lower part, this one broad range inner is able to make ideal products roll from lamina to plank

5、Operating under the security of two fixed roll, roll up and down on, move around, do not work with mobile work roll, operations safely.

6、 The overall structure , the basis is simple, convenient movement, device uses a whole-chassis, do not need to bolt, the basis is simple, the movement of workplace is convenient..

7、Many kinds of shapes of the O-type, U-type, multi-paragraph R, cone cylinder auxiliary device, you can roll a range of cone-cylinder. O-bending : bending the back way; U-bend: the way forward bending. Bend with type R, ways of combination.

Selection Guide

Our company has three series of the three rolls plate bending machine

——GJW11S Hydraulic pre-bending

GJW11 Hydraulic Non-bending

GJW11Mechanical Symmetrical

HOW CAN CHOOSE THEM?

WHAT ARE THE DIFFRENCES BETWEEN THEM?

Technical Parameter

|

Model |

Max.Roll Thickness |

Max.Roll width |

Upper roller diameter |

Side Roller diameter |

Motor |

|

mm |

mm |

mm |

mm |

Kw |

|

|

GJW11S-12*2000 |

12 |

2000 |

250 |

145 |

5.5 |

|

GJW11S-12*3000 |

12 |

3000 |

290 |

150 |

7.5 |

|

GJW11S-16*2000 |

16 |

2000 |

260 |

150 |

7.5 |

|

GJW11S-16*3000 |

16 |

3000 |

330 |

165 |

11 |

|

GJW11S-20*2000 |

20 |

2000 |

310 |

165 |

15 |

|

GJW11S-20*3000 |

20 |

3000 |

375 |

200 |

Y18.5 |

|

GJW11S-25*2500 |

25 |

2500 |

380 |

220 |

22 |

|

GJW11S-25*3000 |

25 |

3000 |

410 |

220 |

22 |

|

GJW11S-30*2500 |

30 |

2500 |

410 |

235 |

22 |

|

GJW11S-30*3000 |

30 |

3000 |

450 |

250 |

30 |

|

GJW11S-35*2500 |

35 |

2500 |

450 |

250 |

30 |

|

GJW11S-35*3000 |

35 |

3000 |

500 |

260 |

37 |

|

GJW11S-40*2500 |

40 |

2500 |

500 |

260 |

37 |

|

GJW11S-40*3000 |

40 |

3000 |

540 |

275 |

45 |

|

GJW11S-45*3000 |

45 |

3000 |

590 |

300 |

45 |

|

GJW11S-50*3000 |

50 |

3000 |

610 |

340 |

55 |

Pre-service:

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order with us.

Aftersales-service

1.We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

2.All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can’t solve your problem , our engineer will go to your factory to help you on spot.

3.Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Contact US

Mary

Nantong Guoji Machinery Equipment Co. LTD

E-mail: info@guojimachine.com

Mobile/Wechat: +86 18796137573

QQ:570506110

| Previous:GJW11Y-60X2500 |

| Next:GJW11S-40X3200 |